News, Uncategorized @vi

Wood Coatings For Export Furniture-Biochem’s Journey to Conquer the World’s Most Demanding Buyers

1. From In-Factory Wood Coatings to Meeting Export Furniture Standards

In the export wood coatings for export furniture industry, “beauty” alone is not enough. Demanding markets such as Europe, the U.S., and Japan impose strict regulations. Above all, the coating layer must pass a series of rigorous performance and safety tests. This makes export-grade wood coatings a decisive factor—on par with product quality and design.

International buyers typically require:

- User and applicator safety: Coatings must be free from harmful chemicals and must not cause respiratory irritation.

- Environmental compliance, low VOC: The coating must demonstrate ultra-low emissions, contributing to reduced pollution and aligning with the global green building trend.

- International certifications: Standards such as Greenguard Gold, EN71.3, IKEA Standard, REACH act as the “passport” for entry into demanding markets.

- Application performance and durability: The coating must dry quickly, form a strong protective film, resist abrasion, and preserve long-lasting aesthetics.

Therefore, export wood coatings are not merely a surface protection layer—they represent a story of technology, testing, and quality commitment. With the growing demand for green buildings and eco-friendly furniture, coating manufacturers must choose the most sustainable path to keep pace with the market—starting from safe raw materials to low-emission production technologies.

2. Breaking the Limits of Traditional Solvent-Based Coatings

For many years, solvent-based coatings have been the popular choice thanks to their advantages— such as strong mechanical durability, water resistance, and moisture protection. However, once entering the export arena, their limitations become increasingly evident:

- High VOC levels (≥ 300g/L): Emissions exceed international standards, making it difficult to pass environmental inspections.

- Strong odor and toxicity: Affecting both worker and end-user health.

- Multiple steps and slow drying: Increasing labor costs, extending finishing time, and putting large-scale industrial production at a disadvantage.

- Challenging compliance with new environmental regulations: As EU and US markets tighten controls on chemicals, worker safety, and carbon emissions.

Wood coatings must evolve to keep up with market trends.

In response, Biochem water-based wood coatings were developed specifically to meet export requirements:

- Low VOC (<130g/L): Safe and fully compliant with international environmental standards.

- Fast drying (30–60 minutes at room temperature): Boosts productivity and shortens the production cycle.

- Safe for workers and factories: Free from heavy metals, formaldehyde, isocyanates, and harmful aromatic solvents.

- Consistent gloss and hardness: Ensures that finished products are both visually appealing and highly durable.

This forms the foundation for Vietnamese manufacturers to strengthen their competitive position in the global supply chain. At the same time, they must continue to enhance coating performance, durability, and overall product quality to stay ahead.

3. Biochem’s Journey to Winning Over the Most Demanding Buyers

International buyers rarely take marketing claims at face value. They trust tests, data, and certifications.

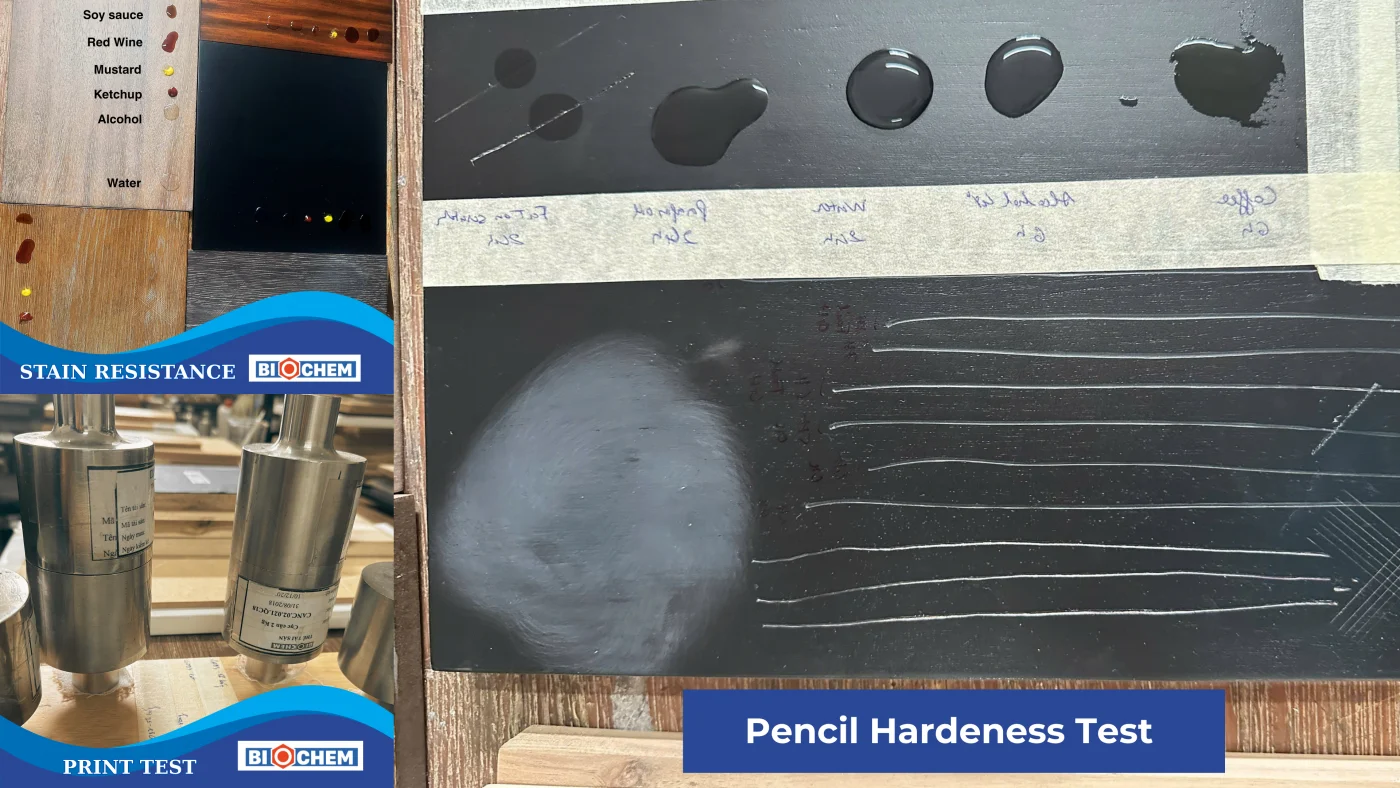

That’s why Biochem chose to prove quality through real-world performance testing:

- Block Resistance: Ensures that two coated surfaces do not stick, deform, or peel when stacked during storage or shipping — a critical factor for container exports.

- Imprint Resistance: Demonstrates that the surface does not leave marks under pressure, ideal for tables, cabinets, chairs, and wooden flooring.

- Stain Resistance: Tests the coating’s ability to resist stains from coffee, wine, cooking oil, mustard, and more. European buyers often require this test for kitchen, dining, and living room furniture.

- Abrasion Resistance: Shows that the finish retains its color and gloss even after repeated friction, crucial for surfaces that see frequent contact, such as floors and tabletops.

- UV Resistance: Proves that the coating maintains its color, resists yellowing, and withstands outdoor exposure for 2–5 years.

All these tests are conducted according to international standards (ASTM, ISO, DIN).

The results show that Biochem coatings are not just “green” on paper — they are genuinely durable and reliable in real-world use. giấy, mà thực sự bền vững và đáng tin cậy trong thực tế sử dụng.

4. From Safety Assurance to Export Advantage

Winning the trust of demanding buyers is never easy, but Biochem has successfully partnered with many international furniture exporters. The benefits include:

- Shorter production and packaging time: Only 3–4 basic steps, with drying completed within hours — compared to several days with solvent-based coatings.

- 20–30% overall cost savings: Thanks to reduced material consumption, lower labor costs, and more efficient operations.

- Full compliance with international audits: From IKEA factory audits and EU environmental inspections to Japanese importers’ strict requirements.

- Enhanced reputation and brand value: Giving Vietnamese manufacturers a clear competitive edge in the global market.

Once buyers gain confidence in the quality, “wood coatings for furniture export” becomes more than just a product — it becomes a bridge connecting Vietnamese furniture to the world.

Biochem Wood Coatings – The Shortcut to Global Export Success

At Biochem, we believe that true export success is built on consistency and proven performance.

With our water-based, low-VOC wood coatings, a wide range of interior and exterior systems, and comprehensive international testing, we are committed to helping Vietnamese manufacturers:

- Build a sustainable competitive advantage.

- Meet the global green building trend.

- Strengthen their reputation and product quality in the most demanding markets.

If you’re looking for a wood coating solution that meets international export standards, let Biochem be your trusted partner on the journey to winning over global buyers. hành trình chinh phục buyer toàn cầu bạn. Chúng tôi không những đồng hành mà còn cung cấp giải pháp tối ưu nhất.

Tiếng Việt

Tiếng Việt 简体中文

简体中文